Inquiry

UL9540A: 2025 Interpretation of Thermal Runaway Fire Propagation Test and Evaluation Methods for Energy Storage Systems!

In recent years, with the rapid development of the global energy storage industry, the installed capacity of lithium-ion Battery Energy Storage Systems (BESS) has continued to rise. However, the safety of energy storage systems has always been a central concern, especially with the increasing frequency of fire and explosion incidents triggered by thermal runaway. These not only threaten personal safety but can also lead to massive property losses.

Against this backdrop, the UL9540A standard has emerged as the authoritative global guide for safety testing of energy storage systems. Every update to this standard draws significant attention across the industry. On March 12, 2025, UL officially released ANSI/CAN/UL9540A-2025 "Thermal Runaway Fire Propagation Testing for Battery Energy Storage Systems", which comprehensively upgrades the testing and evaluation methods for thermal runaway fire propagation. The goal is to provide more scientific and stringent validation tools for the safe design of energy storage systems. This article provides an in-depth analysis of the key innovations in the updated standard from the perspectives of technical details, testing logic, and industry impact.

Why Has Thermal Runaway Fire Propagation Testing Become Central?

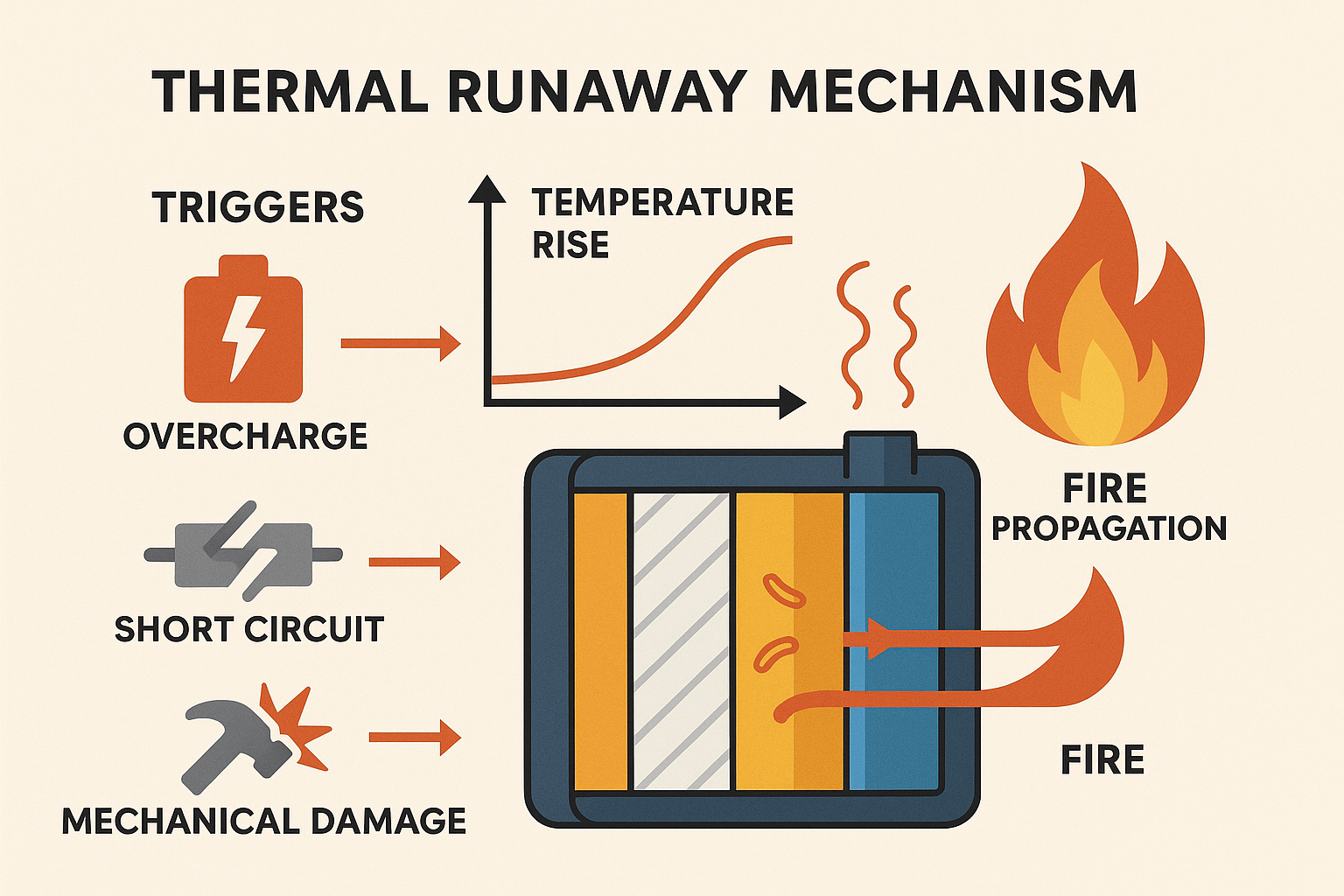

1. The Nature and Hazards of Thermal Runaway

Thermal runaway refers to a self-sustaining exothermic chain reaction in lithium-ion batteries, triggered by internal short circuits, overcharging, mechanical damage, etc. It is characterized by a rapid rise in temperature (exceeding 800°C), gas ejection (including flammable and explosive gases), and potential chain reactions in adjacent cells, ultimately resulting in system-level fires.

2. Limitations of Traditional Testing

Earlier standards mainly focused on the safety testing of individual cells or small modules. However, energy storage systems typically consist of thousands or even tens of thousands of cells, with complex structural designs and thermal conditions, making fire propagation pathways hard to predict. Traditional methods fail to adequately reflect the real-world risks of fire spread.

3. Breakthroughs in UL9540A:2025

The 2025 edition introduces, for the first time, a “full-scale, system-level thermal runaway fire propagation evaluation framework,” emphasizing multi-tiered, progressive testing from cell → module → cabinet → full system. It constructs risk models using quantifiable data to support design optimization.

Core Upgrades in UL9540A:2025 Testing Methods

1. Refined Testing Levels

The new version defines four progressive test levels, each with clear objectives:

- Level 1 (Cell Level): Determine the thermal runaway trigger conditions (e.g., nail penetration, heating plate temperature threshold), ejected materials, and combustion characteristics.

- Level 2 (Module Level): Evaluate the propagation speed, temperature distribution, and gas diffusion path when a single cell enters thermal runaway.

- Level 3 (Unit Level - Cabinet/Sub-system): Simulate real heat dissipation conditions and structural designs, analyze flame spread extent, smoke concentration, and toxicity.

- Level 4 (Installation Level - Full System): Integrate fire suppression and ventilation systems to verify system-level mitigation effectiveness.

Key Requirement: Tests must use production-equivalent BMS (Battery Management Systems) and thermal management designs to ensure data authenticity.

Interpretation of Thermal Runaway Fire Propagation Test

2. Expanded Data Collection Dimensions

The 2025 edition adds several critical metrics:

- Thermodynamic Parameters: Cell surface temperature rise rate, internal pressure variation curves;

- Gas Analysis: Real-time monitoring of harmful gases like hydrogen, CO, and hydrogen fluoride (HF);

- Flame Propagation Speed: Quantified using high-speed cameras and infrared thermal imaging;

- Fire Suppressant Effectiveness: Evaluation of agents like FK-5-1-12 and water mist in suppressing thermal runaway.

Insight: The multi-dimensional data enables the construction of a "thermal runaway propagation map" that can guide optimization in cell spacing, insulation materials, and firefighting strategies.

3. Mandatory Multi-Cell Failure Scenarios

To address industry pain points, the new standard mandates testing of two extreme scenarios:

- Worst-Case Cell Position: Choose the cell with the poorest heat dissipation as the trigger point;

- Simultaneous Multi-Cell Failure: Simulate the effect of multiple concurrent thermal runaway events under severe failures (e.g., BMS malfunction).

Case Study: A manufacturer discovered during testing that when an edge cell entered thermal runaway, the metal cabinet frame conducted heat, accelerating the heating of adjacent modules—leading to a design upgrade with thermal barrier coatings.

Three Major Innovations in the Evaluation Process

1. Risk-Based Safety Threshold Design

UL9540A:2025 introduces the concept of "Thermal Runaway Propagation Time (TRPT)", requiring that system designs must satisfy:

TRPT ≥ T (T = fire response time + personnel evacuation time).

Fire response time should be tailored to specific applications (e.g., residential vs. grid-side). For grid-side systems, TRPT ≥ 30 minutes is typically required to ensure fire systems can activate in time.

2. Coupled Simulation and Real-World Validation

The standard encourages the use of digital twin technology, where CFD (Computational Fluid Dynamics) simulations are used to predict propagation paths before physical testing, and actual test data is used to calibrate the model. This approach significantly reduces testing costs, especially for large-scale systems.

3. Mandatory Dynamic Evaluation Reports

The 2025 version requires test reports to include:

- Sensitivity analysis of thermal runaway trigger conditions;

- Propagation differences at varying ambient temperatures (20°C to 50°C);

- The impact of aging (e.g., after 5,000 cycles) on safety.

Significance: Shifts the focus from simply "passing the test" to "lifetime safety design."

Overview of Key Impacts

- Improved Flexibility: Optional FTIR and ramp heating methods provide testing flexibility.

- Wider Applicability: Adds test coverage for lead-acid, nickel-cadmium, and high-temperature batteries.

- Enhanced Safety: Revised flame spread criteria and new deflagration analysis reduce fire spread risks.

- Simplified Testing: Residential testing now allows for test wall setups, potentially reducing test complexity.

This version emphasizes clarity, safety, and technical inclusivity, aligning with battery technology development and evolving regulatory needs.

Industry Impact and Recommended Responses

1. Higher Technical Barriers Driving Innovation

- Cell Level: High-stability electrolytes (e.g., semi-solid-state), high-temperature-resistant separators become essential;

- System Level: Phase change materials, aerogel insulation, directional venting designs gain popularity;

- Fire Protection Systems: Multi-tiered suppression (e.g., cell-level inhibitors + cabinet-level water mist) becomes mainstream.

2. Testing Cost and Time Challenges

Full four-level testing may take over six months and cost over a million USD. Recommendations:

- Collaborate early with certification bodies to develop pre-testing plans;

- Use modular designs to minimize repeated testing;

- Join industry alliances to share some test data.

3. A “Passport” for Global Market Access

UL 9540A is not only a mandatory standard in the U.S. and Canada, but is also widely adopted internationally—referenced in installation regulations for energy storage systems in Singapore, Malaysia, and Victoria, Australia. The 2025 version aligns further with China’s GB/T36276, helping Chinese companies expand abroad.

Click to learn more about ACE Battery's products with UL9540A certification:

RESS-E20-L0 | 6.6kWh-119.7kWh Modular Home Battery Storage

RESS-BM-L1 | 5.12kWh Lithium ion Battery for Home Energy Storage

RESS-E20-BB | 3.3kWh ESS Battery Module

C&I-EnerBlock: Outdoor C&I Battery Energy Storage System

C&I-EnerCube: Containerized C&I Energy Storage System

Conclusion

UL 9540A evaluates system safety in the event of thermal runaway fire propagation and is the only consensus standard referenced for large-scale fire testing in NFPA 855.

The release of UL9540A:2025 marks a shift from reactive response to proactive prevention in energy storage safety. For manufacturers, this is not only a compliance challenge but also an opportunity to gain market edge through differentiated safety design. Looking ahead, with the integration of AI and advanced sensing technologies, thermal runaway testing may achieve real-time, high-precision early warnings — and the foundation for that future lies in the deep understanding and implementation of today's standards.

Our expert will reach you out if you have any questions!