Inquiry

ODM Battery Systems: Streamlined Power Solutions from Design to Delivery

As energy storage technologies evolve and the demand for flexible power solutions grows, more brands and system integrators are turning to ODM battery systems to streamline product development and accelerate time-to-market. For businesses aiming to deliver high-quality energy solutions without the overhead of in-house R&D, ODM (Original Design Manufacturing) provides a practical, scalable pathway.

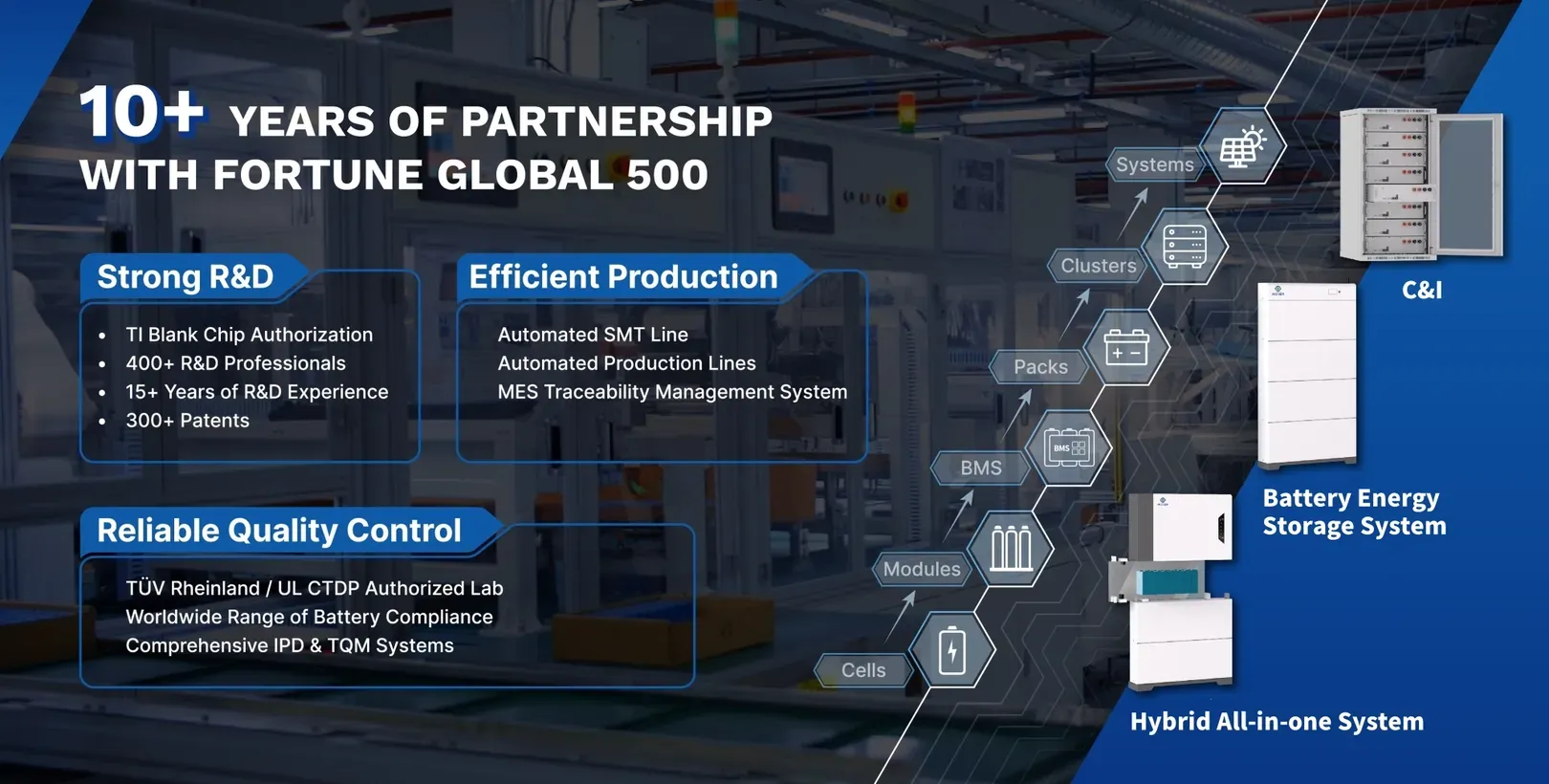

At ACE Battery, we specialize in providing full-cycle ODM battery solutions tailored to the specific needs of energy storage system (ESS) applications. With 13+ years of experience in lithium battery design and manufacturing, our team offers not just production capabilities—but deep engineering expertise that supports long-term energy strategies.

What Are ODM Battery Systems?

ODM battery systems are complete, ready-to-deploy battery solutions designed and manufactured by a supplier, which clients can rebrand or integrate into their own energy storage applications. Unlike OEM (Original Equipment Manufacturer) models, where the client provides design specifications, ODM providers, like ACE Battery, handle the entire design, engineering, prototyping, and certification process.

This approach is ideal for:

- Companies without internal battery development teams

- Fast-growing brands needing fast deployment

- Projects requiring a certified, proven base platform that can be adapted to specific needs

The result? Lower R&D costs, faster market entry, and reduced technical risk—without compromising product quality or performance.

The ACE ODM Battery Process: From Cell Selection to System-Level Delivery

At ACE Battery, our ODM battery development follows a structured, end-to-end process—from initial scenario analysis to system-level testing and delivery. Each stage is handled by a dedicated team of specialists, ensuring every custom lithium battery pack is reliable, application-ready, and compliant with international standards.

From Battery Cells → Modules → BMS → Packs → Systems, here’s how we build your solution:

1. Analyzing Application Scenarios – Tailoring Parameters for Your System

We begin by evaluating your real-world deployment environment. Our engineering solutions team works closely with your system experts to understand energy demands, voltage range, space limitations, and communication protocols. This ensures that every ODM battery system is built on a clear technical foundation aligned with your project goals.

2. Selecting the Right Battery Cells – Balancing Performance and Safety

Our battery cell experts carefully select high-reliability lithium-ion cells based on your application’s requirements—whether for residential ESS, telecom backup, or mobile power. We consider thermal behavior, cycle life, and safety margins to ensure performance stability at the cell level.

3. Designing the Electronic Architecture – Safe, Redundant, and Compliant

Our electronics team develops functional schematics and performs DFMEA analysis to reduce system-level risks. All circuits are designed in accordance with UL991 hardware safety standards, and MTBF (Mean Time Between Failures) simulations ensure critical components achieve >300,000 hours of reliability—essential for long-lasting ODM battery systems.

4. Developing the BMS Software – Reliable Logic, International Standards

We design the BMS logic to match the electronic framework and your system control needs. All firmware complies with UL1998 and IEC60730 standards for software safety. Static code analysis and multi-layer protection logic are implemented to ensure your custom lithium battery operates securely and efficiently in every condition.

5. Engineering the Mechanical Structure – Thermal and Stress Simulation

Our structural design team performs 3D simulations for thermal management, mechanical stress, and explosion-proof integrity. Following UL9540 design principles, we ensure your battery pack is not only compact and rugged—but also optimized for heat dissipation, vibration resistance, and environmental durability.

6. Assembling the Engineering Prototype – Controlled, Clean, and Precise

Once the electronics, software, and structure are finalized, we build the engineering prototype under strict quality controls. ESD protection, plasma cleanliness, and cleanroom protocols ensure that every prototype reflects the final production-grade system in terms of quality and integration.

7. Verifying Performance and Reliability – Stress Testing from −40°C to 70°C

The completed prototype is then tested by our product reliability verification team. Tests include HALT (Highly Accelerated Life Testing), ESD/EFT electromagnetic interference, and lightning surge simulations. Systems are validated in temperature extremes from −40°C to 70°C to guarantee robust operation in any deployment scenario.

By combining domain expertise across hardware, software, mechanical, and validation engineering, ACE Battery delivers fully verified ODM battery systems ready for seamless integration—from the cell to the complete energy storage system.

Why Choose ACE Battery for ODM Energy Storage Systems?

The value of a successful ODM partnership lies in trust, engineering quality, and reliability. ACE Battery has built its reputation as a dependable ODM battery system provider by aligning deep technical insight with real-world application needs.

Here’s what makes us different:

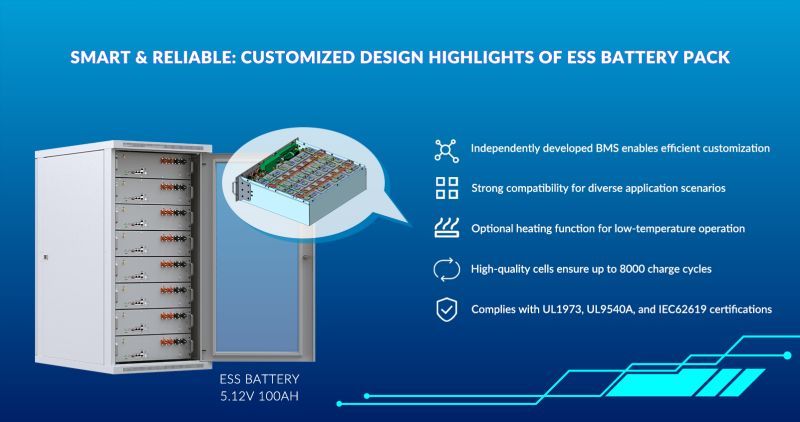

- Independently Developed Smart BMS

We provide tailored battery control logic, with strong compatibility across use cases such as residential ESS, telecom backup, and mobile power stations.

- Customization-Ready Architecture

Our modular approach allows rapid parameter adjustment—from voltage levels and pack dimensions to communication protocols—without requiring full redesign.

- Low-Temperature Heating Option

For deployments in extreme climates, our heating function ensures safe operation down to -20°C.

- Long Lifecycle, High-Quality Cells

Using A-grade LiFePO4 cells with consistent sourcing, our battery packs offer up to 8000 charge-discharge cycles, minimizing long-term replacement costs.

- Certified & Compliant

We support compliance with key global standards: UL1973, UL9540A, and IEC62619. That means faster project approvals and smoother international deployment.

Whether your project is in North America, Europe, or the Middle East, we understand the certification roadmaps and integration constraints that energy professionals face.

Application Scenarios for ACE ODM Battery Systems

ACE Battery’s ODM battery packs are trusted across a variety of energy storage applications, including:

- Residential and community energy storage systems (ESS)

- Commercial and industrial battery storage

- UPS backup power systems

- Solar + battery hybrid systems (on-grid/off-grid)

- Marine Power Applications

- Cold-climate energy storage (with heating)

Each scenario has unique technical requirements—whether it’s depth of discharge, peak-shaving capability, safety redundancy, or form factor constraints. Our ODM process is structured to adapt to these variables quickly and cost-effectively.

What to Look for in an ODM Battery Manufacturer

Selecting an ODM battery supplier isn’t just about unit cost—it’s about long-term partnership and technical compatibility. Here are key criteria to consider:

| Criteria | Why It Matters |

|---|---|

| In-house R&D and BMS control | Enables deeper customization and integration options |

| Proven ESS application focus | Ensures design choices align with real-world storage needs |

| Certification experience | Speeds up regulatory approval and market entry |

| Modular production capability | Allows scaling from pilot to mass production |

| IP protection & transparency | Safeguards your brand and market positioning |

At ACE Battery, we meet all of the above—and more. Our clients benefit from a blend of agility, engineering reliability, and manufacturing strength that helps them stay competitive in fast-changing energy markets.

Let’s Build Your Custom Energy Storage Solution

If you're seeking a smart, adaptable, and fully supported ODM battery system for your next energy storage project, ACE Battery is ready to partner with you.

We offer:

- Flexible ODM platforms for rapid customization

- Complete certification support for international deployment

- Technical assistance and upgrade pathways

Let’s connect and explore how ACE Battery can help you bring your energy vision to life—on time, on budget, and beyond expectations.

Contact our team to get started with a tailored proposal.

Frequently Asked Questions (FAQ)

Q: What's the typical development lead time for an ODM battery system?

A: For standard configurations, sample delivery can take 3–4 weeks. Full custom projects may require 6–10 weeks depending on complexity.

Q: Can I brand the battery with my own logo and packaging?

A: Yes, we support white-label branding and customized packaging based on your requirements.

Q: Do you support small batch orders for pilot projects?

A: Absolutely. We offer flexible MOQ options for prototyping and low-volume deployments.

Q: How do you ensure product safety?

A: All products undergo multiple tests including overcharge, short-circuit, thermal abuse, and vibration. Safety is our top priority.

Our expert will reach you out if you have any questions!