Inquiry

ACE Battery’s Lithium Supply Chain for ODM Energy Storage Projects

In today’s energy storage landscape, success in ODM projects hinges on more than technical specs or a competitive price. It often comes down to one decisive factor: the quality of your supply chain. Without it, even the most innovative designs can stall in delays, compliance issues, or inconsistent deliveries.

At ACE Battery, we’ve seen it happen—and we’ve built our lithium battery supply chain to help you avoid it. Whether you’ve struggled with unpredictable lead times, slow iteration cycles, or regional certification headaches, we understand the stakes. That’s why we’ve built a smarter supply chain—one that’s agile, traceable, and optimized for ODM success.

Why the Energy Storage Supply Chain Matters in ODM Projects

ODM (Original Design Manufacturing) energy storage projects require close collaboration between brands and battery manufacturers. But without a resilient supply chain, even the best engineering can be delayed, derailed, or diluted.

Common frustrations we help solve include:

- Unpredictable lead times and shipping delays

- Limited flexibility for small-batch or seasonal production

- Lack of part-level traceability and audit readiness

- Challenges in meeting US grid standards or EU safety regulations

- Inventory waste from rigid forecasting and slow iterations

In the fast-evolving lithium battery space, a smarter, integrated supply chain becomes your project’s lifeline—minimizing risk while maximizing responsiveness.

ACE Battery’s End-to-End ODM Supply Chain Architecture

From cell sourcing to final system delivery, ACE Battery offers a vertically integrated, digitally controlled supply chain purpose-built for ODM energy storage success.

1. Full Lifecycle Coverage

ACE manages the full lifecycle of lithium battery systems:

- Cell selection & testing

- Module assembly & pack design

- BMS development & system integration

- Cabinet/container-level assembly

- Packaging, logistics, and recycling

Whether for residential ESS, commercial BESS, RV power systems, or lithium batteries for medical carts, our infrastructure supports high-mix, variable-volume production with consistency and compliance.

2. Smart Traceability and Digital Systems

ACE Battery ensures full visibility and accountability across every production stage through:

- ERP (Enterprise Resource Planning) for synchronized material and workflow management

- MES (Manufacturing Execution System) for real-time production control

- WMS (Warehouse Management System) for inventory tracking

- RFID-based traceability, enabling part-level visibility from cell to final system

ACE Battery uses a fully digital MES and RFID traceability system to ensure that every cell, module, and pack is verifiably traceable from sourcing to delivery.

This level of control significantly reduces mix-up risks and accelerates quality audits, helping ODM clients meet stringent global compliance needs—whether that’s CE marking in Europe or UL testing for the U.S. market.

3. Built for ODM Flexibility

Unlike traditional battery factories focused on volume, ACE is structured for agility:

- Small-batch production lines dedicated to rapid prototyping

- Quick version switching to support iterative development cycles

- 7 cross-functional engineering teams (mechanical, thermal, electrical, BMS, and more)

- Support for VMI (Vendor-Managed Inventory) and JIT (Just-in-Time) delivery

To address frequent iteration challenges in lithium battery ODM projects, ACE offers dedicated small-batch production lines and fast version switching support—helping clients cut prototyping time by up to 30%.

This flexibility ensures smoother transitions from design to validation to full-scale production.

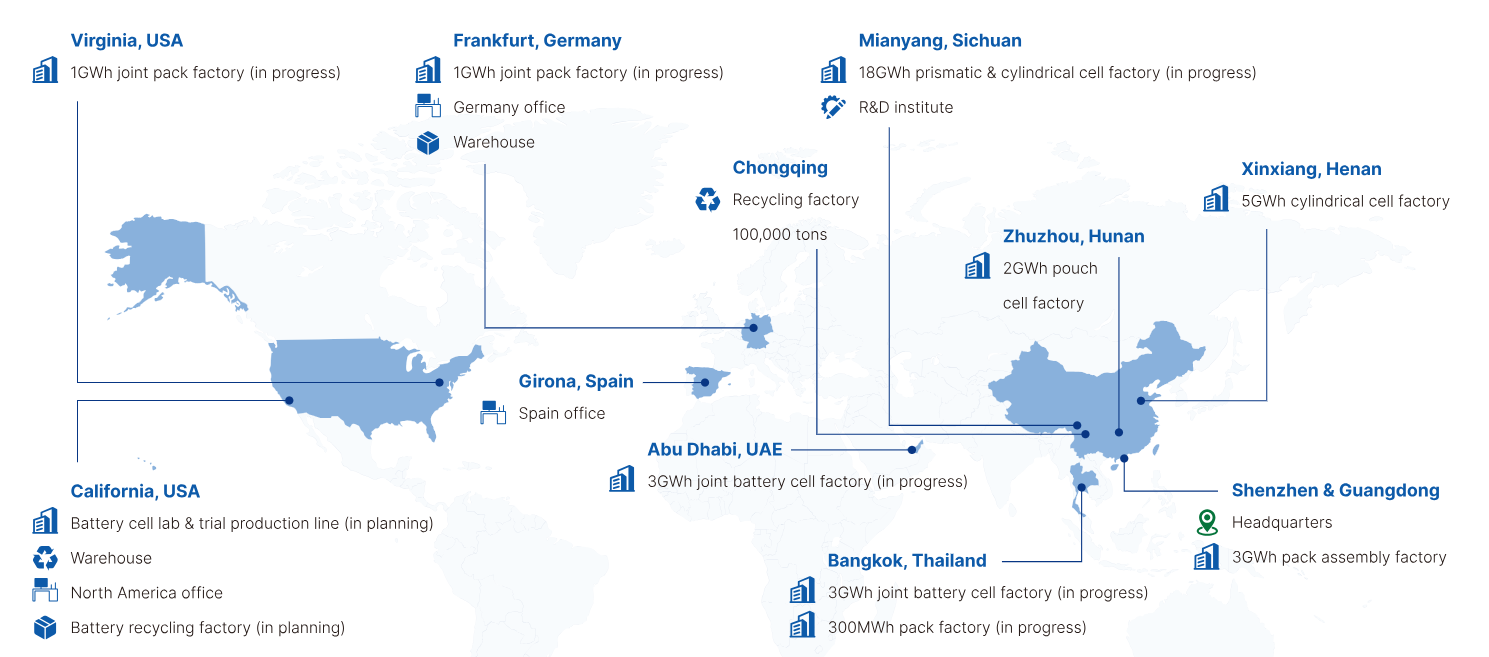

4. Global Reach with Local Support

Our manufacturing network spans multiple regions, enabling:

- Localized production and delivery, shortening lead times and reducing tariffs

- 24/7 technical support teams to assist across time zones

- On-site support for system integration, testing, and training

ACE’s global production footprint and localized support help ODM clients accelerate deployment while complying with regional safety and grid standards, including VDE-AR-N norms in Germany and UL requirements in America.

5. Built-in Sustainability and ESG Compliance

Sustainability is not an afterthought—it’s embedded in our supply chain:

- Closed-loop battery recycling programs

- Compliance with CE, UN38.3, RoHS, and other certifications

- Green packaging and logistics practices

- Support for clients’ ESG reporting requirements

By integrating closed-loop recycling and global certifications, ACE helps ODM clients reduce their carbon footprint while meeting investor and regulatory ESG expectations.

How Do We Power ODM Scenarios?

ACE Battery supports a wide range of ODM use cases, including:

- Residential energy storage brands needing fast design-to-market cycles

- Commercial BESS developers requiring scalable, modular systems with regional customization

- Medical equipment lithium battery OEMs demanding strict traceability and safety compliance

- Outdoor portable power brands seeking flexible volumes and seasonal production

| ODM Challenge | ACE Battery Solution |

|---|---|

| Long lead times | Regional production + JIT delivery |

| Small-batch production constraints | Dedicated rapid-prototype lines |

| Poor traceability | RFID-enabled MES + WMS systems |

| Slow version iteration | Cross-functional teams + agile workflows |

| Compliance complexity | Pre-certified components + global test support |

| ESG & sustainability pressure | Closed-loop recycling + certified green practices |

Why It Works: The ACE Supply Chain Advantage

ACE’s lithium battery supply chain for ODM projects is more than a set of tools—it’s a synchronized ecosystem designed to:

- Align with your product roadmap

- Mitigate supply and regulatory risks

- Reduce engineering bottlenecks

- Increase production visibility and speed

- Support long-term growth and compliance

By combining agile production methods, intelligent systems, and global-local infrastructure, we empower your success at every stage of the product lifecycle.

Ready to Streamline Your ODM Supply Chain?

If you’re navigating inconsistent timelines, compliance hurdles, or inflexible supply models, ACE Battery can help you break through.

We don’t just manufacture batteries—we deliver an energy storage supply chain built for resilience, speed, and scale.

Our expert will reach you out if you have any questions!